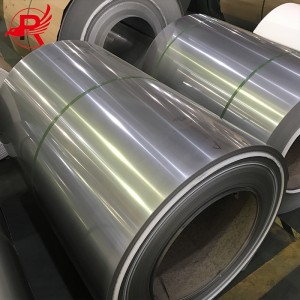

Lamina Duplex Frigida Laminata ASTM A240 2205 2507 Chalybs Inoxidabilis

| Nomen Producti | Spira chalybis inoxidabilis 2205 2507 |

| Gradus | 201/EN 1.4372/SUS201 |

| Duritia | 190-250HV |

| Crassitudo | 0.02mm-6.0mm |

| Latitudo | 1.0mm-1500mm |

| Margo | Scissura/Fresa |

| Tolerantia Quantitatis | ±10% |

| Diameter Internus Nuclei Chartacei | Nucleus chartaceus Ø500mm, nucleus diametro interno speciali, et sine nucleo chartaceo ad petitionem emptoris |

| Superficies Finis | NO.1/2B/2D/BA/HL/Perterritus/6K/8K Speculum, etc. |

| Involucrum | Pallet ligneus/Arca lignea |

| Conditiones Solutionis | Depositum TT 30% et reliquum 70% ante vecturam, LC 100% ad conspectum |

| Tempus Traditionis | VII-XV dies laboris |

| Minimum Quotae Money (MOQ) | Ducenti chiliogrammata |

| Portus Navigationis | Shanghai/Ningbo portum |

| Exemplum | Exemplum spirae chalybis inoxidabilis 2205 2507 praesto est. |

Chalybs inoxidabilis 2205 2507, qui optimam suturabilitatem, bonam resistentiam corrosionis et magnam firmitatem praebet. Materia aptissima est ad amplam varietatem applicationum, inter quas sunt apparatus ad cibum praeparandum et apparatus ad chemica tractanda.

Sequitur index nonnullarum applicationum communiorum pro spiralibus chalybis inoxidabilis 2205 2507:

1. Instrumenta ad Cibum Tractandum et Instrumenta ad Chemica Tractanda

2. Industriae Petrolei et Gasii

3. Applicationes Marinae

Nota:

1. Libera exemplatio, 100% post-venditionem qualitatis cura, quemvis modum solutionis sustine;

2. Omnes aliae specificationes tuborum rotundorum chalybis carbonis secundum requisita tua praesto sunt (OEM et ODM)! Pretium officinae a ROYAL GROUP accipies.

Compositiones Chemicae Spirae Chalybis Inoxidabilis

| Compositio Chemica % | ||||||||

| Gradus | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 - 5.5 | 16.0 -18.0 | - |

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0.0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| CCCXVI | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16.0 -1 8.0 | 2.0 - 3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| DCXXX | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| DCXXXI | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 - 0.22 | 0.24 - 0.26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Tractatio superficialis laminarum chalybis inoxidabilis magni momenti est, quae directe aspectum, resistentiam corrosionis et campos applicationis laminarum chalybis inoxidabilis afficit. Tractationes superficiales communes laminarum chalybis inoxidabilis 2B, BA, NO.4, et cetera includunt.

Tractatio superficialis 2B est frequentissima, cum meliore splendore et levitate, et apta est plerisque applicationibus cum requisitis generalibus, ut constructione, supellectili, et cetera.

Curatio superficialis BA per polituram electrolyticam obtinetur, et politura superficialis altior est. Apta est occasionibus cum requisitis altis politurae superficialis, ut in vasis coquinariis, instrumentis electricis, et cetera.

Superficies tractata numero quarto per polituram taeniae obtinetur, et superficies texturam pruinam ostendit. Apta est occasionibus quae ornatum et resistentiam scalpendi requirunt, ut in tabulis ornatis, interioribus ascensorum, et cetera.

Praeter supradictas communes methodos tractationis superficiei, spirae chalybis inoxidabilis etiam secundum necessitates emptorum aptari possunt, ut puta politura speculi, tractio filorum, et cetera, ut necessitatibus specialibus variorum agrorum satisfaciant.

Tractatio superficialis laminarum chalybis inoxidabilis maximi momenti est ad usum finalem et functionem. Tractationes superficiales communes laminarum chalybis inoxidabilis includunt 2B, BA, NO.4, et cetera.

Tractatio superficialis 2B est frequentissima, meliore splendore et levitate praedita, et apta est plerisque applicationibus cum requisitis generalibus, ut constructione, supellectili, etc. Haec methodus tractationis decaptationem superficialem post frigidam laminationem adhibet ut superficies levior fiat, sed effectum speculi non habet.

Curatio superficialis BA per polituram electrolyticam obtinetur. Superficies altior est et effectum specularem ostendit. Apta est occasionibus ubi altam superficiem requiritur, ut in vasis coquinariis, instrumentis electricis, et cetera. Haec curatio aspectum excellentem et resistentiam corrosionis praebet.

Superficies tractata numero 4 per polituram taeniae obtinetur, et superficies texturam pruinam ostendit. Apta est occasionibus quae ornatum et resistentiam scalpturae requirunt, ut in tabulis ornatis, interioribus ascensorum, et cetera. Haec methodus tractationis ornatum et pulchritudinem spirae chalybis inoxidabilis augere potest, simul resistentiam eius attritionis augens.

Praeter supradictas communes methodos curationis superficiei, spirae chalybis inoxidabilis etiam secundum necessitates emptorum aptari possunt, ut puta politura specularis, tractio filorum, et cetera, ut necessitatibus specialibus variorum artium satisfaciant. Ergo, electio methodi curationis superficiei aptae pro spirabus chalybis inoxidabilis magni momenti est ad effectum finalem et applicationem producti.

Processus productionis spirae chalybis inoxidabilis est: praeparatio materiae rudis - recoctio et decapatio - (tritura intermedia) - laminatio - recoctio intermedia - decapatio - laminatio - recoctio - decapatio - aequatio (tritura et politura producti finiti) - sectio, involucratio et repositio.

Involucrum et arcae conditio laminarum chalybis inoxidabilis nexus magni momenti sunt ad salutem transportationis producti et ad qualitatem producti tuendam. Typice, involucrum et arcae conditio laminarum chalybis inoxidabilis his gradibus sequuntur:

Primum omnium, spirae chalybis inoxidabilis diligenter inspiciendae sunt antequam in capsas congerantur, ut superficies a scalpturis et contaminationibus libera sit, et requisitis ac normis emptorum respondeat.

Deinde, materias involucri idoneas secundum specificationes et quantitatem rotulorum chalybis inoxidabilis elige. Inter materias involucri communes sunt palletae ligneae, scatulae, pelliculae plasticae, et cetera. Pro magnis rotulis chalybis inoxidabilis, plerumque in palletis ligneis convasantur ut producta non comprimantur et deformentur in transportatione.

Deinde, chartas inoxidabiles super materias involucri ordinate compone, et congruas cautiones tutelae adhibe, ut palletas ligneas firmando, pellicula plastica involvendo, et cetera, ne collidantur et detrimentum capiantur in transportatione.

Denique, spirae chalybis inoxidabilis inclusae notantur et recensentur, cum specificationibus producti, quantitate, die productionis aliisque notitiis, et clarae inscriptiones identificationis involucris ad facilem identificationem et administrationem adnectuntur.

Per totum processum invasionis et implicationis, necesse est stricte secundum normas et requisita pertinentia operari, ut ne spirae chalybis inoxidabilis durante transportatione laedantur et ut qualitas atque integritas producti ad emptorem perveniant.

Vectura:Expressa (Traditio Exemplaris), Aerea, Ferrea, Terrestre, Maritima (FCL vel LCL vel Massa)

Q: Suntne fabricatores UA?

A: Ita, fabricatores sumus. Officinam nostram propriam in urbe Tianjin, Sinis, habemus. Praeterea, cum multis societatibus publicis, velut BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, et cetera, cooperamur.

Q: Possumne mihi mandatum experimentale tantum aliquot tonnas habere?

A: Scilicet. Onus tibi per ministerium LCL mittere possumus. (Minus onus continentis)

Q: Si exemplum gratuitum?

A: Exemplar gratuitum, sed emptor pro vectura solvit.

Q: Esne auri praebitor et mercaturam fideiussorem facis?

A: Septem annos auri praebitores sumus et commercium fideiussorem accipimus.